Concrete plywood is becoming increasingly integral to modern construction projects due to its durability, versatility, and cost-effectiveness. The combination of concrete and plywood offers a unique solution for a variety of construction needs, particularly in projects that prioritize long-lasting materials. This article delves into various aspects of concrete plywood, including its definition, manufacturing process, importance in construction, unique properties, advantages, and the challenges associated with its use.

Understanding Concrete Plywood

Definition and Key Features of Concrete Plywood

Concrete plywood is a composite material that combines plywood with a concrete layer, resulting in a strong and durable product suitable for various construction applications. Unlike traditional plywood, which is primarily made of wood and is prone to wear and tear, concrete plywood integrates the strength of concrete with the lightweight and versatile nature of plywood.

Some key features of concrete plywood include:

- High Strength: Its composite nature allows it to withstand heavy loads and resist damage.

- Moisture Resistance: The concrete layer provides excellent resistance to water and humidity, making it ideal for outdoor applications.

- Fire Resistance: Concrete plywood has a higher fire resistance than standard plywood, enhancing its safety in construction.

Additionally, concrete plywood is often designed with a variety of finishes, allowing for aesthetic flexibility in architectural applications. This versatility makes it suitable not only for structural elements but also for decorative purposes, such as wall panels and facades. The ability to customize the surface finish means that architects and builders can achieve unique looks while maintaining the structural benefits of the material.

The Manufacturing Process of Concrete Plywood

The manufacturing process of concrete plywood involves several key steps that contribute to its structural integrity and performance. Initially, high-quality plywood is selected as the base material. This plywood is often treated to enhance its durability and water resistance.

Next, a layer of concrete is applied to one or both sides of the plywood. This layer can be either precast or poured on-site, depending on the specifications of the project. Once set, the combination is cured to ensure maximum bonding and strength. The final product is then subjected to quality control tests to ensure it meets the necessary standards for construction use.

Moreover, advancements in technology have led to the development of innovative techniques in the manufacturing of concrete plywood. For instance, the incorporation of additives and reinforcements, such as fiberglass or steel mesh, can further enhance the material’s performance characteristics. This not only improves its tensile strength but also increases its resistance to cracking and deformation under stress. As a result, concrete plywood is becoming increasingly popular in high-demand construction environments, such as commercial buildings and infrastructure projects.

The Importance of Durability in Construction

Factors Contributing to Construction Durability

Durability is a critical criterion in the construction industry as it directly affects the lifespan and maintenance costs of structures. Several factors contribute to the overall durability of a building:

- Material Quality: The selection of high-quality materials is essential for enhancing durability.

- Environmental Conditions: Buildings need to withstand the specific weather and environmental conditions of their location.

- Design and Engineering: Proper engineering practices ensure that structures can handle loads and stresses over time.

The Impact of Material Selection on Durability

The materials chosen for a construction project have a direct impact on its durability. Using materials like concrete plywood, which combines the strengths of both concrete and plywood, can significantly enhance a building’s resilience against environmental factors and physical wear.

Furthermore, selecting materials based on their lifecycle durability can result in reduced maintenance costs and less frequent need for repairs or replacements, contributing to the overall sustainability of the construction project. For instance, using weather-resistant coatings or treatments can protect surfaces from moisture and UV damage, extending the life of exterior finishes. Additionally, incorporating recycled materials not only promotes environmental sustainability but can also improve the durability of a structure by leveraging advanced engineering techniques that enhance the performance of these materials.

Another crucial aspect of material selection is the compatibility of materials with one another. When different materials are used in conjunction, it is vital to ensure that they can work together without compromising the structural integrity of the building. For example, the thermal expansion rates of different materials must be considered to prevent cracking or warping over time. This careful consideration of material properties not only enhances durability but also ensures that the building can adapt to changing environmental conditions without significant degradation. Learn more about degradation on https://www.dau.edu/glossary/degradation

Concrete Plywood in Construction

Unique Properties of Concrete Plywood

Concrete plywood possesses several unique properties that make it an appealing choice for a variety of construction projects. For instance, its lightweight nature combined with its high strength allows for easier handling and transportation compared to traditional concrete. This makes it particularly valuable in projects requiring quick assembly and deployment. The material also exhibits excellent durability and resistance to moisture, which is crucial in environments prone to weather fluctuations or flooding. This resilience not only extends the lifespan of structures but also reduces maintenance costs over time.

Additionally, concrete plywood is versatile; it can be used for walls, floors, and roofs, making it suitable for residential, commercial, and industrial applications. Its adaptability is further enhanced by the ability to customize finishes and textures, allowing architects and designers to achieve a variety of aesthetic outcomes while maintaining structural integrity. Furthermore, the integration of insulation materials within concrete plywood can improve energy efficiency, making it an eco-friendly option that aligns with modern sustainable building practices.

Common Uses of Concrete Plywood in Construction

Concrete plywood finds application in numerous construction scenarios, including:

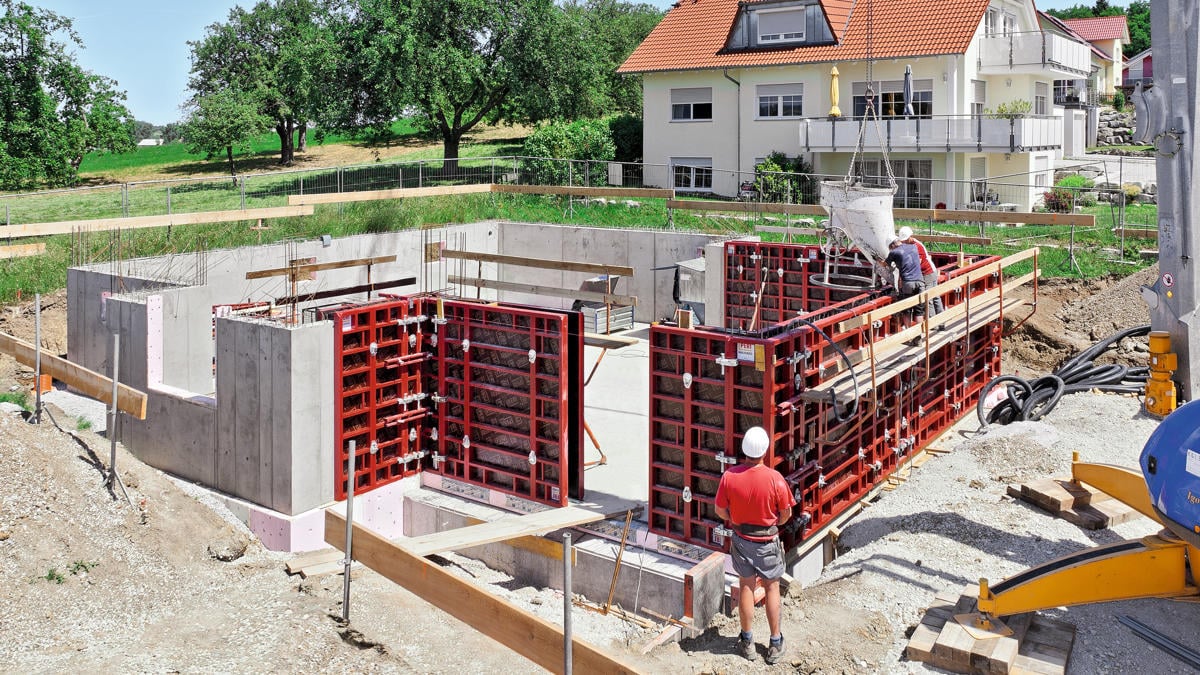

- Formwork: It is often used in forming structures, particularly in the casting of concrete elements.

- Wall Panels: Concrete plywood can be used as prefabricated wall panels to speed up construction times.

- Floor Systems: Its strength and load-bearing capabilities make it suitable for various flooring systems.

In addition to these common uses, concrete plywood is increasingly being utilized in innovative architectural designs, such as modular construction and off-site building techniques. This method allows for significant time savings, as components can be manufactured in a controlled environment and then assembled on-site. Moreover, with the rise of urbanization and the need for efficient space utilization, concrete plywood is also being explored for use in temporary structures, such as pop-up shops and emergency shelters, where speed and adaptability are paramount. Its ability to be easily disassembled and reused further enhances its appeal in a world that is increasingly focused on sustainability and resource conservation.

The Advantages of Using Concrete Plywood

Cost-Effectiveness of Concrete Plywood

One of the most significant advantages of concrete plywood is its cost-effectiveness. While the initial investment may be higher than traditional wood products, the long lifespan and low maintenance requirements ultimately lead to reduced total costs. Additionally, the speed of installation associated with concrete plywood can help save labor costs.

Moreover, its durability minimizes the likelihood of needing repairs or replacements, making it a financially prudent choice in the long run. This durability is particularly beneficial in high-traffic areas or environments exposed to harsh weather conditions, where traditional materials might falter. The resistance of concrete plywood to moisture and pests further enhances its longevity, allowing property owners to allocate their resources more efficiently without the constant worry of upkeep.

Sustainability and Environmental Impact

Concrete plywood also offers advantages in terms of sustainability. The use of durable materials can contribute to less waste over time, as structures are less likely to need frequent replacements. Furthermore, many manufacturers are now sourcing materials in a more environmentally responsible manner, utilizing recycled content and sustainable practices.

This focus on sustainability not only aids in reducing a project’s carbon footprint but also appeals to environmentally conscious consumers and builders alike. The production process for concrete plywood often incorporates energy-efficient methods, which further minimizes environmental impact. Additionally, the thermal mass properties of concrete help regulate indoor temperatures, reducing the need for heating and cooling systems and contributing to energy savings over the lifespan of the building. As green building practices become more prevalent, the demand for materials like concrete plywood is likely to increase, making it a forward-thinking choice for modern construction projects.

Challenges and Solutions in Using Concrete Plywood

Common Issues with Concrete Plywood

Despite its numerous advantages, there are challenges associated with the use of concrete plywood. Some common issues include:

- Moisture Control: While concrete plywood is resistant to moisture, improper installation can lead to water infiltration that may compromise its integrity. To find more about moisture click here.

- Weight Distribution: Miscalculating the load-bearing capacity can result in structural failures.

- Cost Variability: Fluctuations in material costs can affect budgeting and project planning.

Overcoming Challenges in Concrete Plywood Usage

Addressing these challenges requires proactive measures. Proper installation techniques, including adequate supports and waterproofing measures, can minimize moisture-related problems. Moreover, thorough training for construction personnel on the properties and handling of concrete plywood is essential to ensure safe and effective use.

To combat cost variability, builders can engage in thorough market research and consider bulk purchasing options to secure more favorable rates on materials. Additionally, establishing long-term relationships with suppliers can lead to better pricing agreements and more predictable budgeting, allowing for a smoother project execution.

Another critical aspect to consider is the environmental impact of using concrete plywood. Sustainable sourcing of materials can help mitigate negative effects on the ecosystem. By opting for recycled or sustainably harvested wood products, builders not only contribute to environmental conservation but can also appeal to an increasingly eco-conscious market. Furthermore, implementing energy-efficient practices during the construction process can enhance the overall sustainability of projects utilizing concrete plywood.

Finally, regular maintenance and inspections can significantly extend the lifespan of concrete plywood installations. By scheduling periodic evaluations, any early signs of wear or damage can be promptly addressed, ensuring the material continues to perform optimally over time. This proactive approach not only enhances safety but also contributes to the overall cost-effectiveness of using concrete plywood in various construction applications.

Other resources: Concrete Form Plywood Essential Tips for Builders